At Total Plumbing Solutions, we are UV pipe relining specialists.

We apply the latest trenchless techniques to carry out pipe and drainage works without the need for excavation. Not only does this solution offer less disruption to the existing infrastructure and environment, but makes pipes stronger and more reliable in the long term.

TPS have the skills and equipment to reline all pipe materials (RCP, PVC, GRP & AC) and diameters ranging from DN100 – DN1650.

Total Plumbing Solutions are accredited SAERTEX-LINER installers with a strong relationship with our supplier. Their support and backing of specialised engineers who monitor and ensure the highest quality of product and workmanship is part of the service.

SAERTEX provide TPS with structural liners and have a long established history of designing and supplying liners for GRP pipe. We rely on UV-curing of our GRP pipe liners which offer enormous advantages

The unique ECR fiberglass reinforcement that makes up our liner is based on multiaxial fabric technology that withstands high mechanical stresses.

The liner TPS will use is permanently corrosion and chemical resistant and meets all design requirement for all project.

The overall liner will be a homogenous conduit between fittings and no joins are present.

We can also reline box culverts.

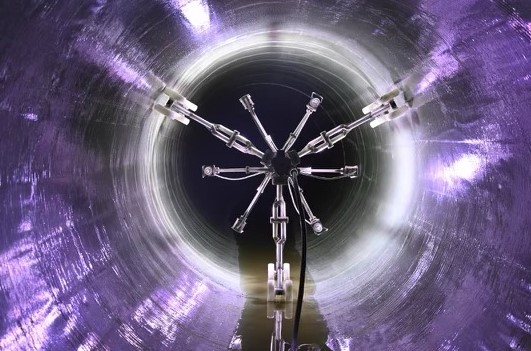

Relining Technology

The Total Plumbing Solutions pipe relining method is based on a non-dig solution. With little to no excavation necessary, the surrounding landscape remains intact and there is no major clean up required. Not only is this process less time-consuming than traditional pipe and drain replacement methods, but it won’t disturb existing the existing flora. Tree roots, roadways, nature strips and gardens are left healthy and intact.

6 Step Relining Process

Step 1

Our process begins with an onsite consultation and CCTV inspection of the drainage system to determine and locate any problems within the drains. The footage is recorded in full colour onto a USB stick, and a complete report is created detailing the findings. General findings may include drain misalignment or collapse, missing sections, water ingress, tree root infestation and ageing infrastructure.

Step 2

We then hydro jet the drains using a high-pressure water cleaner to descale the internal bore of the drain, removing any roots or obstructions, preparing the drain for relining.

Step 3

A custom-made bladder is then inserted into the drain and carefully pulled or pushed into position, spanning over the damage section of the drain.

Step 4

The bladder is the inflated using compressed air which expands and forces the epoxy filled liner to conform and bond to the internal bore of the existing pipe. The liner is then left to cure, creating a pipe within a pipe.

Step 5

Once cured, the bladder is deflated and removed, leaving the newly created structural liner set in place.

Step 6

A final CCTV inspection is conducted, and the pipe is ready for full use, and a lining report is prepared for the client.

Benefits of Pipe Relining

Quicker Installation

Faster than traditional excavation methods and less labour required.Long Term Solution

Pipe relining offers a reliable 20-year life span.Environmentally-friendly

Tree roots, gardens and nature strips remain undisturbed.Lower Cost

With no excavation and pipe laying needed, labour and machine costs are lower.